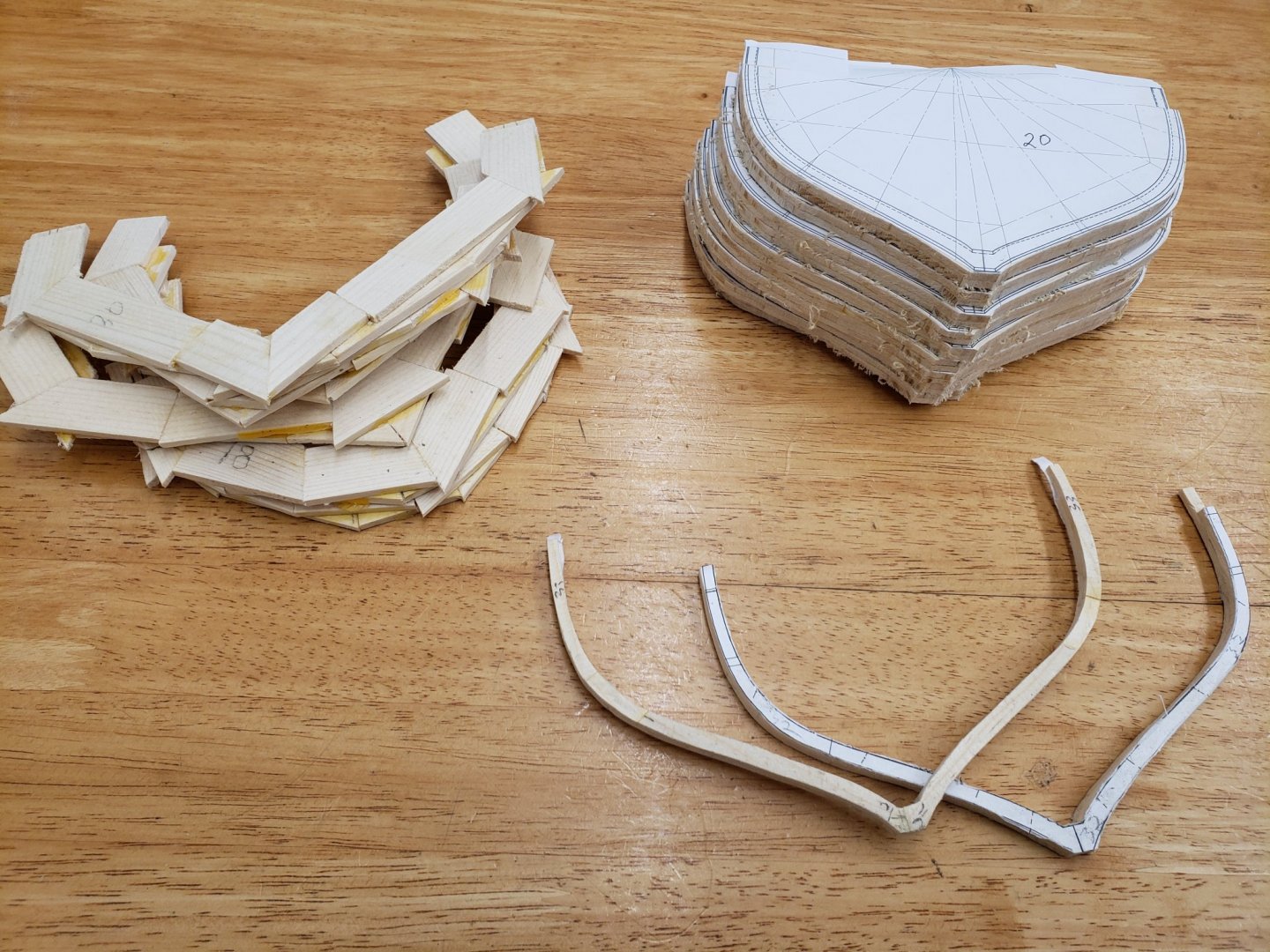

Since this is my first Plank on Frame model, I have a lot to learn about making the frames manually. I’ve always beleived that to automate a process, you need to be able to do it manually to completely understand what is involved. I’ve learned so much just by making these and each frame is made a little different as I learn. My table saw cannot repeatable produce thin strips of wood to the tolerance I would like. I built a thickness planer from a hand planner, but it is real finiky. Even dealing with the paper patterns was tricky. It took me a while to figure out the best method to adhere the paper pattern to the wood. I now use a glue stick and apply it judisiously to the wood, not the paper, as the paper gets soft, wrinkles and expands. So many things to learn.

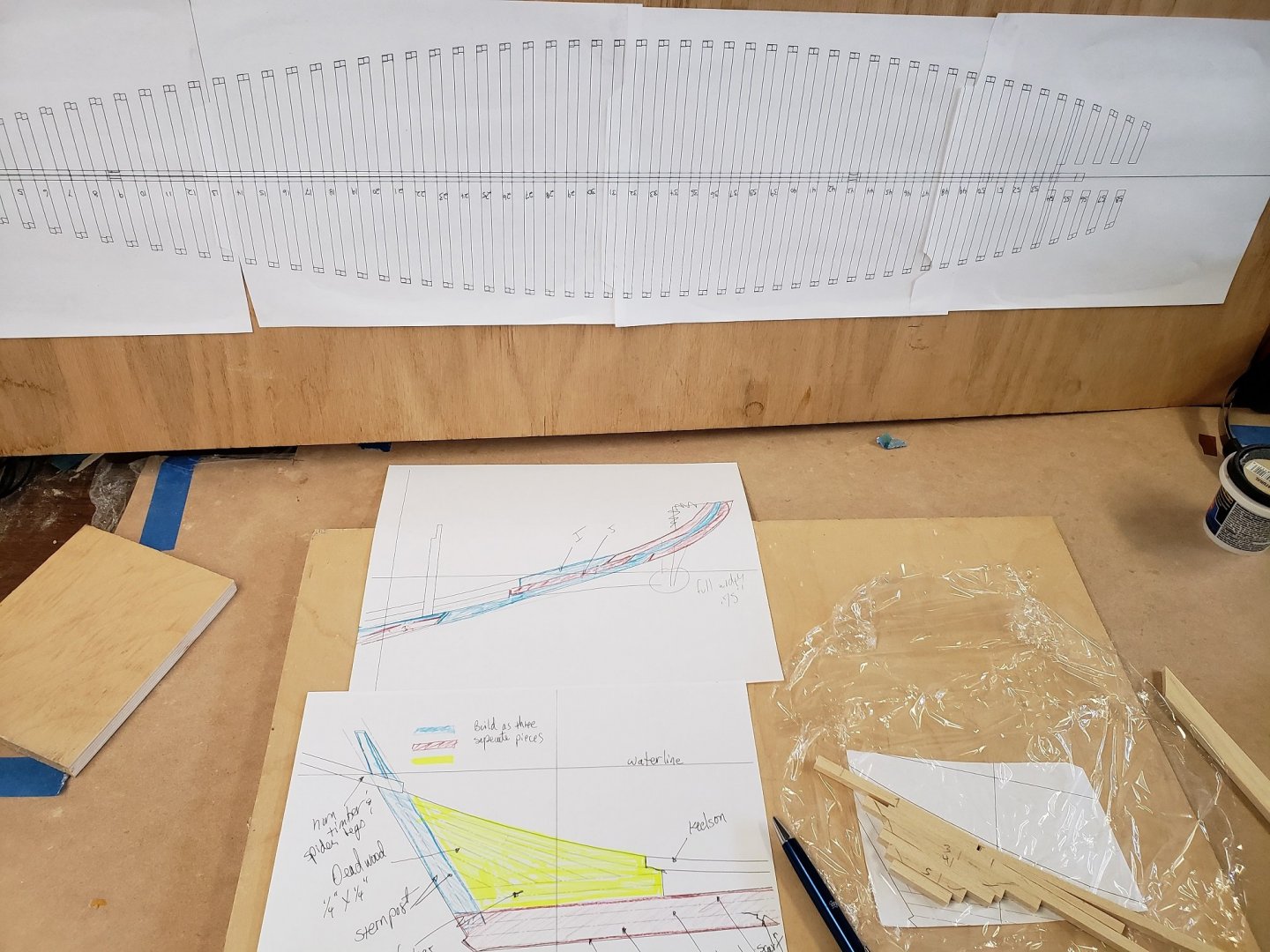

I have created a DXF and PDF file for each frame, front and back.

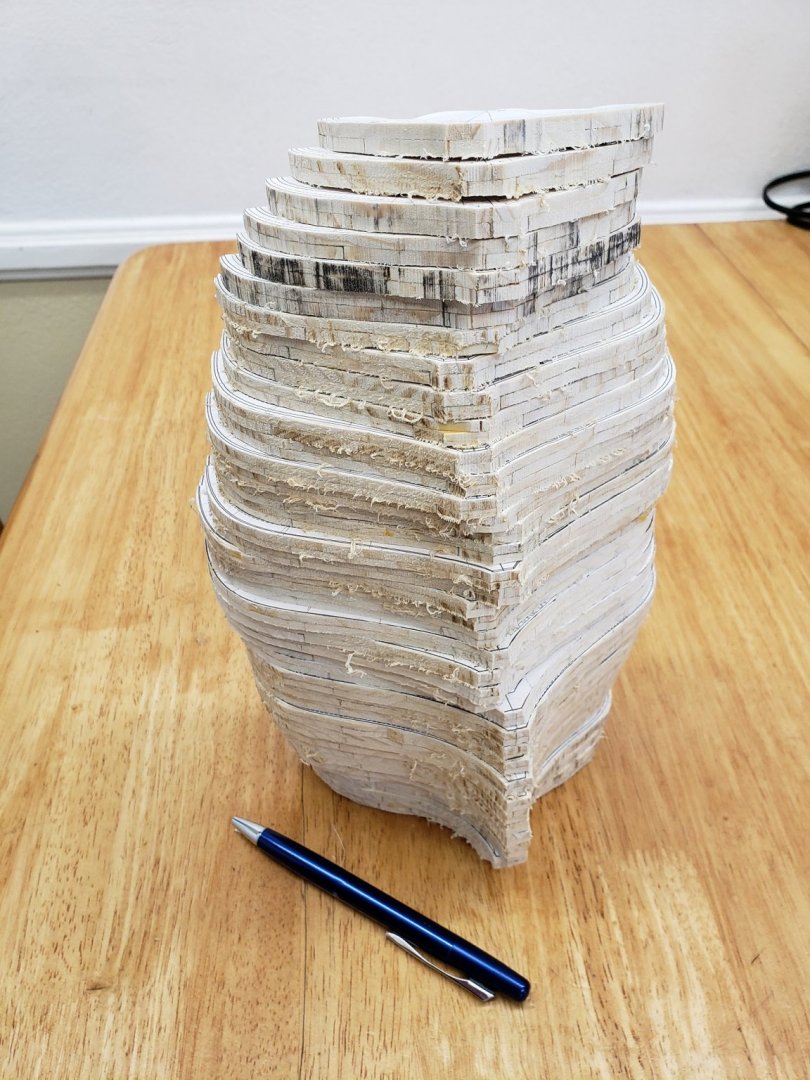

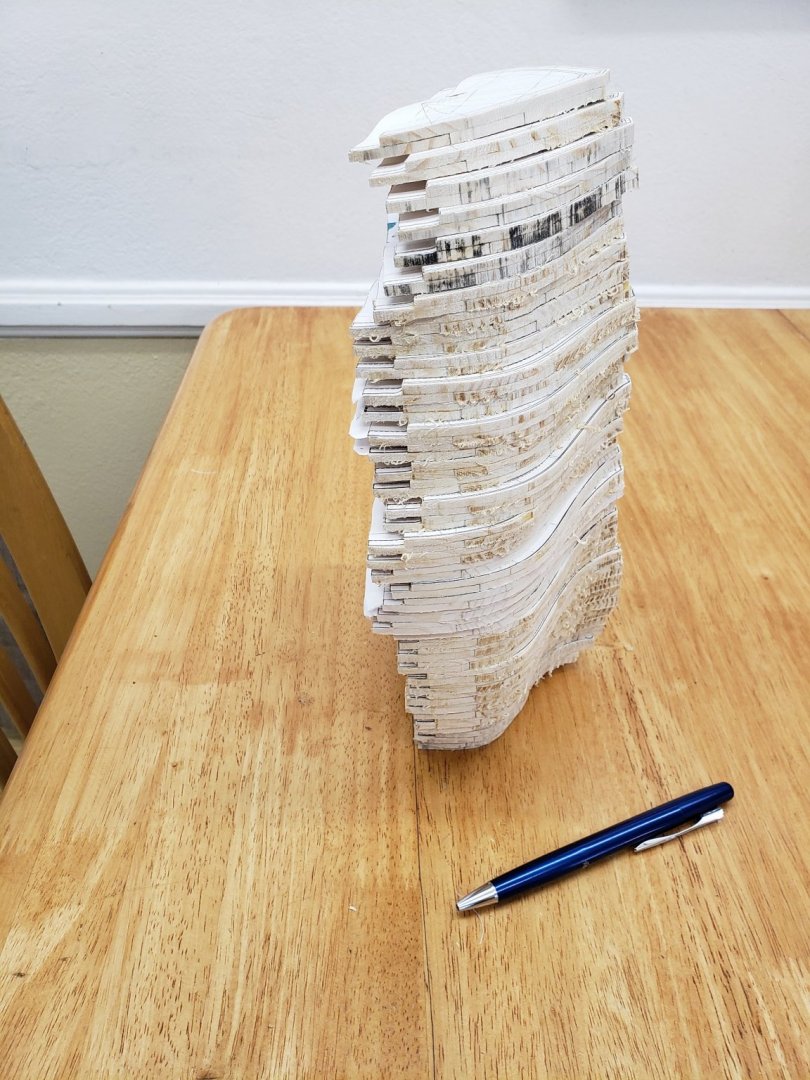

I have finished laying up all of the full frames and have rough cut them on the band saw. Each has thirteen individual pieces of wood.. Now I need to start working on the keel and thinking about the build board. I am going to build this ship right side up 🙂

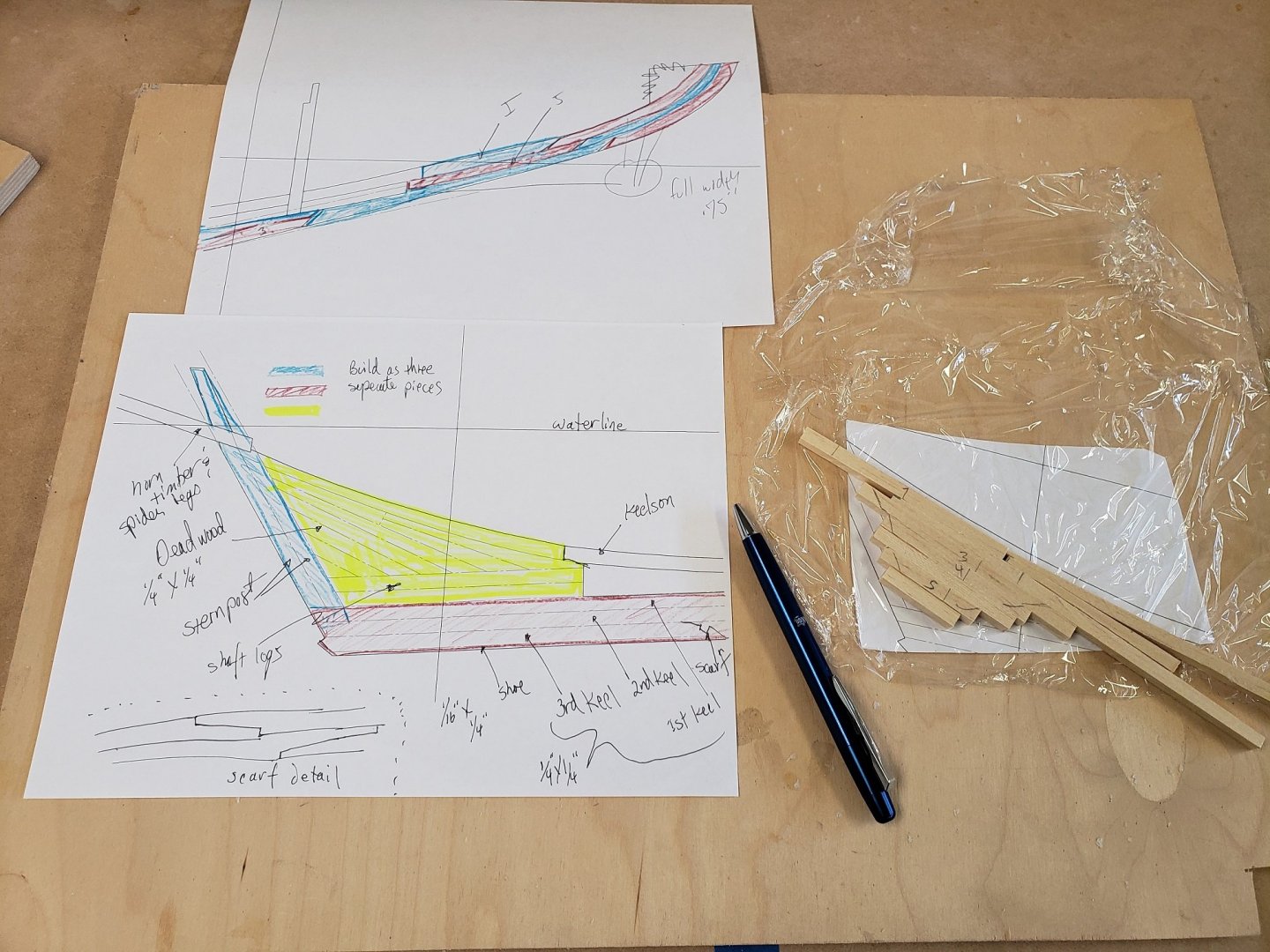

Below is my keel plan, I will build the deadwood oversize. Bond the first second and third keel and the shoe together. I’ll joint the sternpost assembly and the keel assembly with a mortise and tenon joint, then fit the deadwood. I bought some bamboo place mats with some really great looking bamboo for the trenails. I will drive them through the shoe into the keel in several spots.

And finally, I need to get started on the build board, seen in the back ground below. I have some masonite that I will use to support the frames.

Well, back to it. Be safe out there. The wife and I have been wearing a mask and gloves when we need to run an errand or go shopping. Then we wash our hands like the dickens when we return.